In today's fast-paced world, where data transmission plays a crucial role in various industries, fiber optic technology has become the backbone of communication networks. Fiber optic tubes are an essential component of these networks, allowing the transmission of light signals carrying data over long distances. However, you may have noticed that these tubes come in different colors. In this article, we will explore the significance of fiber optic tube colors, their coding standards, advantages, applications, and factors to consider when choosing the right colors for your specific needs.

What are Fiber Optic Tubes?

Before delving into the world of fiber optic tube colors, let's first understand what fiber optic tubes are. Fiber optic tubes, also known as fiber optic cables or optical fibers, are thin, flexible strands made of glass or plastic. They are designed to transmit light signals by confining and guiding the light within the core, thanks to the principle of total internal reflection.

Importance of Fiber Optic Tube Colors

The colors of fiber optic tubes serve a crucial purpose in identifying and distinguishing different fibers within a network. With the increasing complexity of fiber optic systems, the use of specific colors helps technicians and network administrators identify and manage the fibers more efficiently. By using color-coded tubes, they can easily trace, connect, and troubleshoot the network infrastructure, saving time and minimizing errors.

Common Fiber Optic Tube Colors

Fiber optic tubes come in a wide range of colors, each assigned a specific meaning or purpose. While the color options may vary among manufacturers, some common colors include:

- Yellow: Typically used for single-mode fibers, yellow signifies long-distance communication links and backbones.

- Orange: Orange-colored tubes often indicate multimode fibers used for short-range communications within buildings or campuses.

- Aqua: Aqua-colored tubes are commonly associated with 10 Gigabit Ethernet or higher-speed applications.

- Green: Green tubes are often used for fiber optic cables in military and outdoor applications.

- Blue: Blue-colored tubes are sometimes used for fiber optic cables in the telecommunication industry.

- Purple: Purple signifies fiber optic tubes that are used for wavelength division multiplexing (WDM) applications.

- Gray: Gray tubes are typically reserved for cables used in premises or indoor installations.

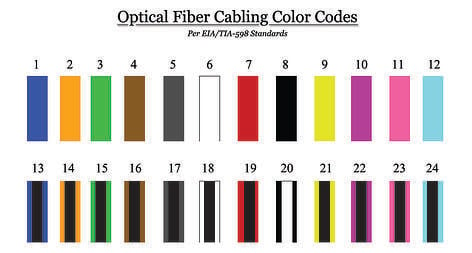

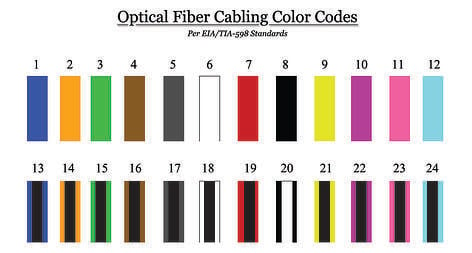

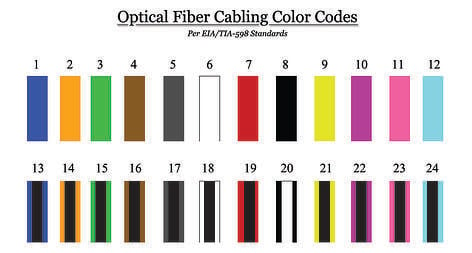

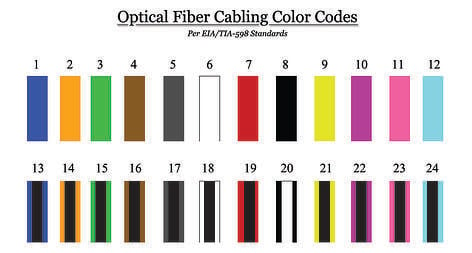

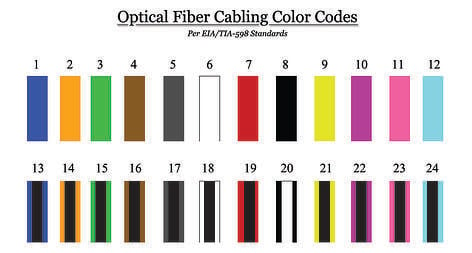

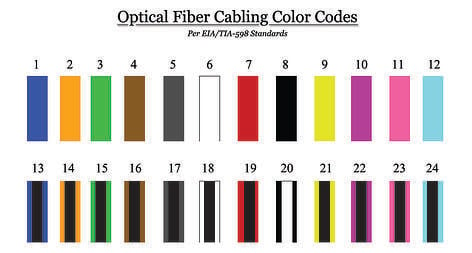

Fiber Optic Tube Color Coding

To ensure uniformity and ease of identification, fiber optic tube colors follow specific coding standards. The most widely adopted color coding standard is the TIA-598-C, issued by the Telecommunications Industry Association (TIA). According to this standard, each color is assigned a specific meaning, allowing technicians to quickly recognize the type and purpose of a fiber optic tube.

The TIA-598-C standard defines the following color scheme:

- Blue: Reserved for single-mode fibers.

- Orange: Typically used for multimode fibers.

- Green: Used for indoor/outdoor cables.

- Brown: Often employed for outdoor cables.

- Slate: Used for underground cables.

- White: Typically used for air-blown fibers.

- Red: Reserved for cables with fire-resistant jackets.

- Yellow: Commonly used for riser cables.

- Violet: Reserved for distribution cables.

- Rose: Typically used for general-purpose cables.

Understanding Fiber Optic Tube Color Standards

While the TIA-598-C standard provides a widely accepted color scheme, it's important to note that different industries and regions may have variations in their color coding standards. Therefore, it is crucial to familiarize yourself with the specific color standards used in your area or industry to ensure accurate identification and maintenance of fiber optic tubes.

Advantages of Using Different Fiber Optic Tube Colors

Using different fiber optic tube colors offers several advantages, including:

- Easy Identification: Color-coded tubes simplify network management and troubleshooting by allowing technicians to quickly identify specific fibers or cable types.

- Reduced Errors: Clear color coding reduces the chances of errors during installation, maintenance, and repairs.

- Enhanced Efficiency: By utilizing different colors for different purposes, such as backbone or distribution fibers, technicians can work more efficiently and avoid confusion.

- Streamlined Maintenance: Color-coded tubes enable faster identification of faulty fibers or cables, reducing downtime during repairs.

- Standardization: Following color coding standards ensures consistency across different network installations, making it easier for technicians to work on diverse systems.

Applications of Fiber Optic Tube Colors

Fiber optic tube colors find application in various industries, including:

- Telecommunications: The telecommunication industry heavily relies on fiber optic networks, where color-coded tubes are used to manage and maintain complex infrastructure.

- Data Centers: In data centers, fiber optic tube colors aid in identifying different fibers and facilitating efficient data transmission.

- Medical Field: Fiber optics play a critical role in medical applications, such as endoscopy and surgical procedures, where color-coded tubes help ensure precision and accuracy.

- Military and Aerospace: Military and aerospace industries utilize fiber optics for secure and high-speed communications, with color coding assisting in system management.

- Industrial Automation: Fiber optic tube colors help streamline automation processes and control systems in industrial environments, ensuring reliable data transmission.

Factors to Consider When Choosing Fiber Optic Tube Colors

When selecting fiber optic tube colors for a specific application, several factors should be considered:

- Network Type: Determine whether the network requires single-mode or multimode fibers and select the appropriate colors accordingly.

- Application: Consider the specific application and the corresponding color coding standards prevalent in that industry.

- Environmental Factors: Evaluate the installation environment, such as indoor or outdoor, and choose colors suitable for the conditions.

- Compatibility: Ensure the chosen colors align with the existing infrastructure to maintain consistency and ease of maintenance.

Best Practices for Working with Fiber Optic Tubes

To ensure optimal performance and longevity of fiber optic tubes, follow these best practices:

- Proper Handling: Handle fiber optic tubes with care, avoiding excessive bending or twisting that may cause damage.

- Cleanliness: Keep the tubes clean by using lint-free wipes and approved cleaning solutions to remove dirt, dust, and contaminants.

- Protection: Employ appropriate protective measures, such as cable trays or conduits, to shield fiber optic tubes from physical damage.

- Testing and Inspection: Regularly test and inspect fiber optic tubes to identify any potential issues or degradation in performance.

- Professional Installation: Whenever possible, engage professional technicians with expertise in fiber optic installations for accurate and reliable results.

Maintenance and Care of Fiber Optic Tubes

To ensure the longevity and optimal performance of fiber optic tubes, it is essential to implement regular maintenance and care practices:

- Inspect fiber optic tubes periodically for signs of damage, such as bends, cracks, or loose connections.

- Keep the tubes clean and free from dust, oil, or other contaminants that may degrade performance.

- Avoid excessive tension or strain on the tubes during installation or handling.

- Store unused fiber optic tubes in a clean and protected environment to prevent damage.

- Follow manufacturer guidelines for cleaning, testing, and maintaining fiber optic tubes.

Conclusion

Fiber optic tube colors play a vital role in the identification, management, and maintenance of fiber optic networks. By following industry-standard color coding schemes and considering specific application requirements, technicians can streamline network operations and minimize errors. Whether in telecommunications, data centers, medical fields, or industrial automation, the proper selection and care of fiber optic tube colors ensure efficient and reliable data transmission.

FAQs

Q1: Can I use any color for fiber optic tubes?

A1: While some flexibility exists in color options, it is best to follow industry-standard color coding schemes to ensure compatibility and ease of maintenance.

Q2: Are fiber optic tube colors standardized worldwide?

A2: While the TIA-598-C standard is widely adopted, variations in color coding schemes may exist in different industries or regions.

Q3: How do fiber optic tube colors aid in troubleshooting?

A3: Color-coded tubes enable technicians to quickly identify and trace specific fibers, making troubleshooting and repairs more efficient.

Q4: Can I change the color of fiber optic tubes after installation?

A4: It is generally not recommended to change the color of fiber optic tubes after installation, as it may cause confusion and inconsistencies in identification.

Q5: Are fiber optic tubes with different colors priced differently?

A5: The price of fiber optic tubes typically does not vary based on color. The cost is primarily determined by factors such as fiber type, length, and quality.

fiber optic tube colors

n a

n a

n a