Inverter VFD Connection: A Comprehensive Guide for Effective Power Control

Unlocking the Potential of Inverter VFD Connection

The Importance of Inverter VFD Connection

Inverter VFD Connection: Step-by-Step Guide

1. Determine the Requirements and Specifications

2. Gather the Necessary Tools and Equipment

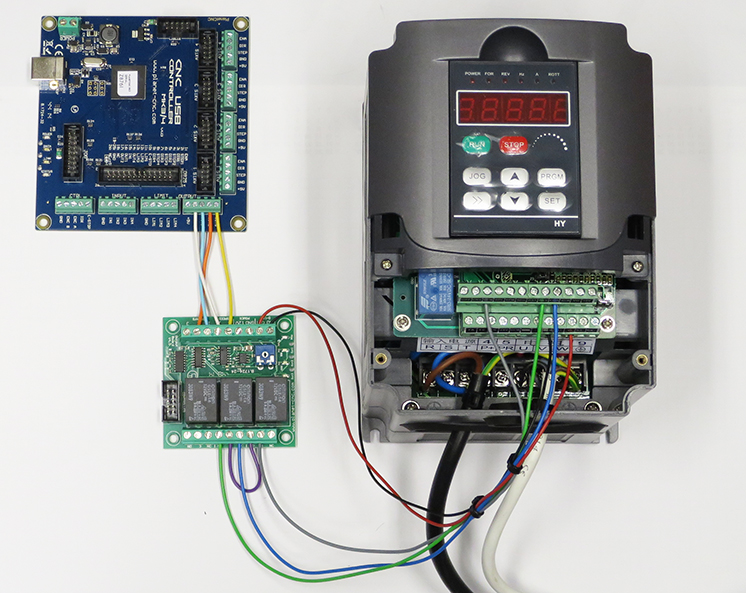

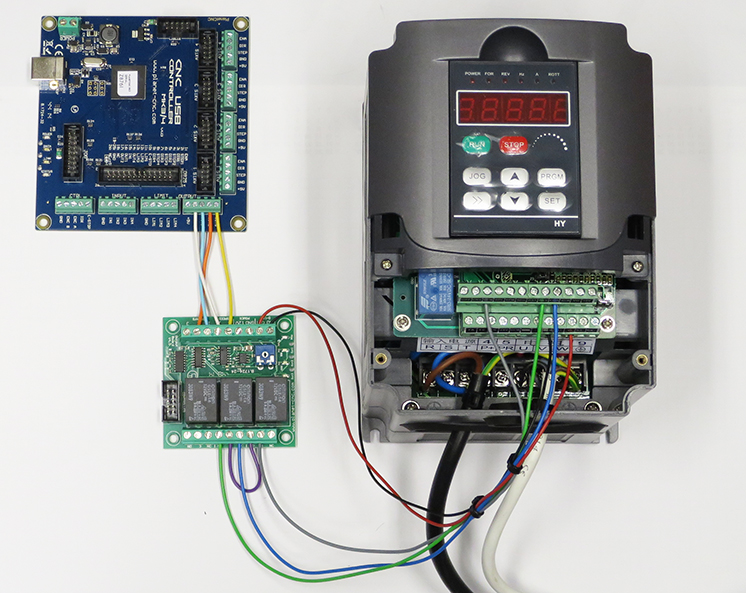

3. Power Down and Isolate the System

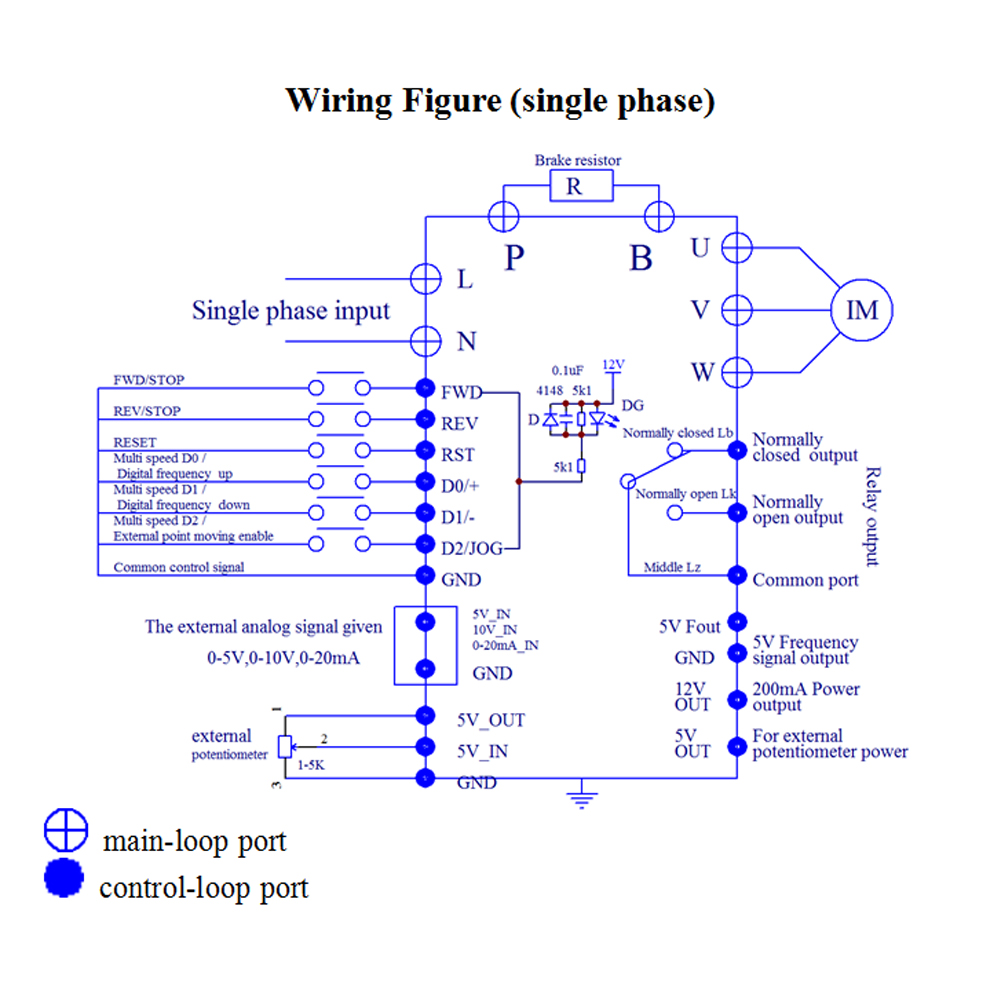

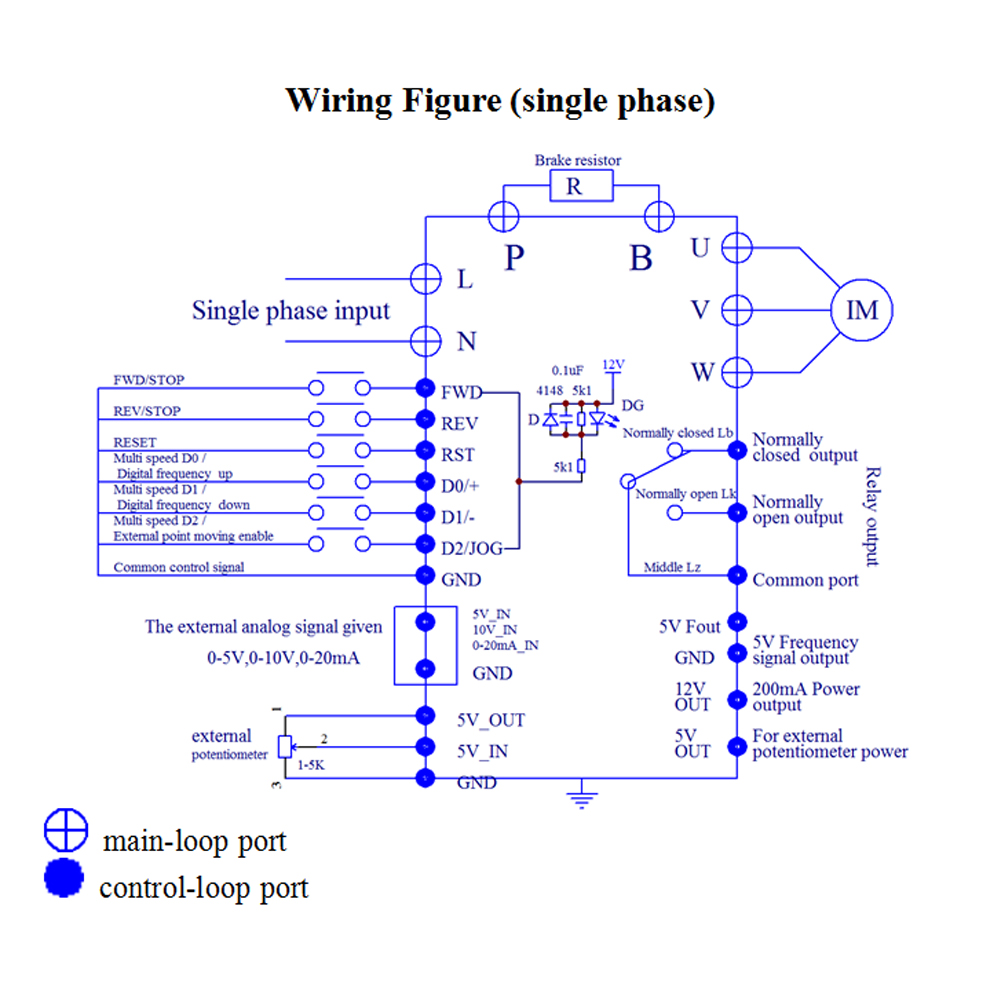

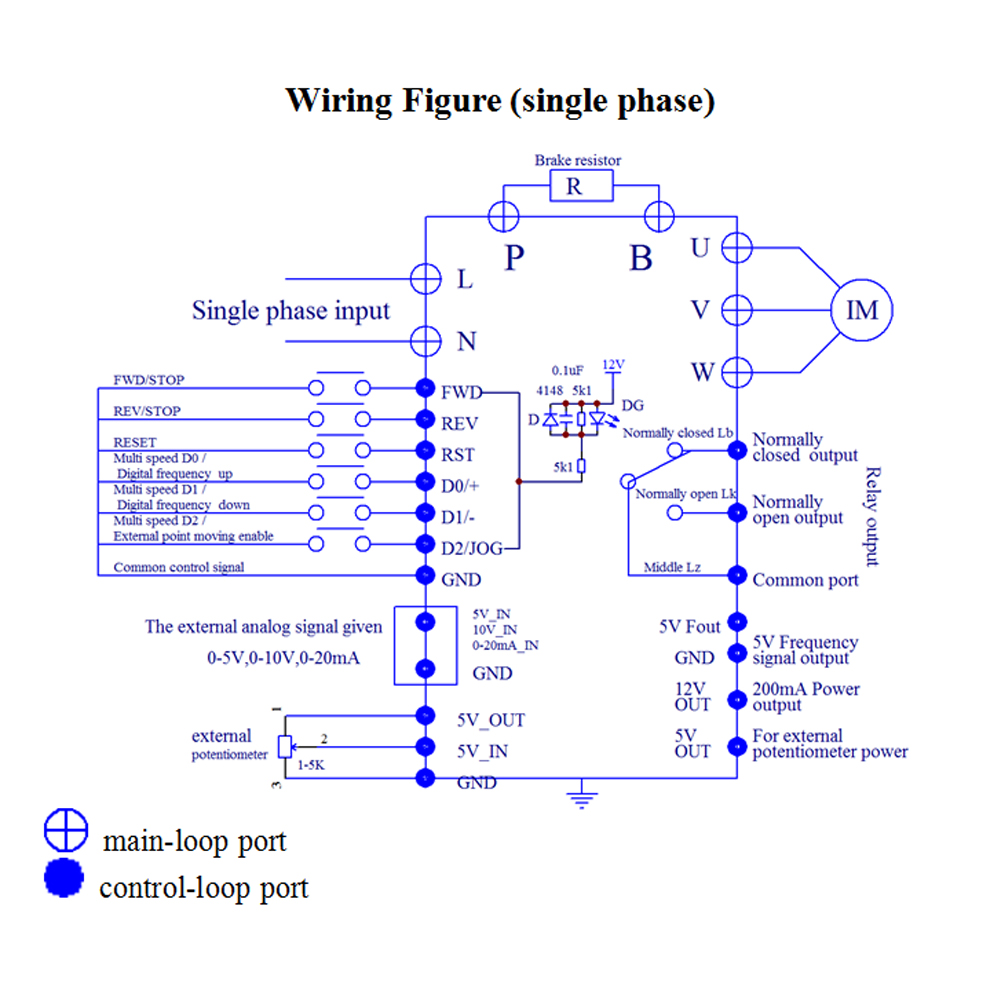

4. Identify the Input and Output Terminals

5. Connect the Power Supply

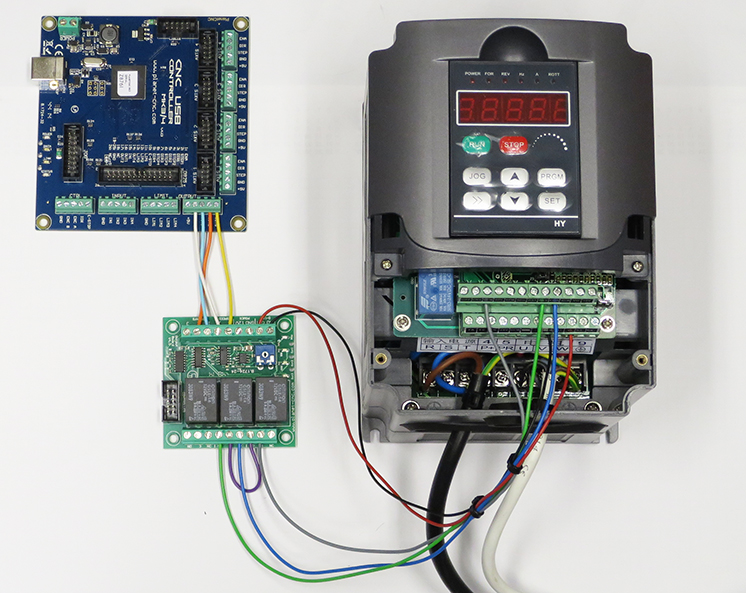

6. Establish the Control Wiring

7. Wire the Motor

8. Double-Check the Connections

9. Power On and Test the System

10. Regular Maintenance and Monitoring

FAQs about Inverter VFD Connection

inverter vfd connection

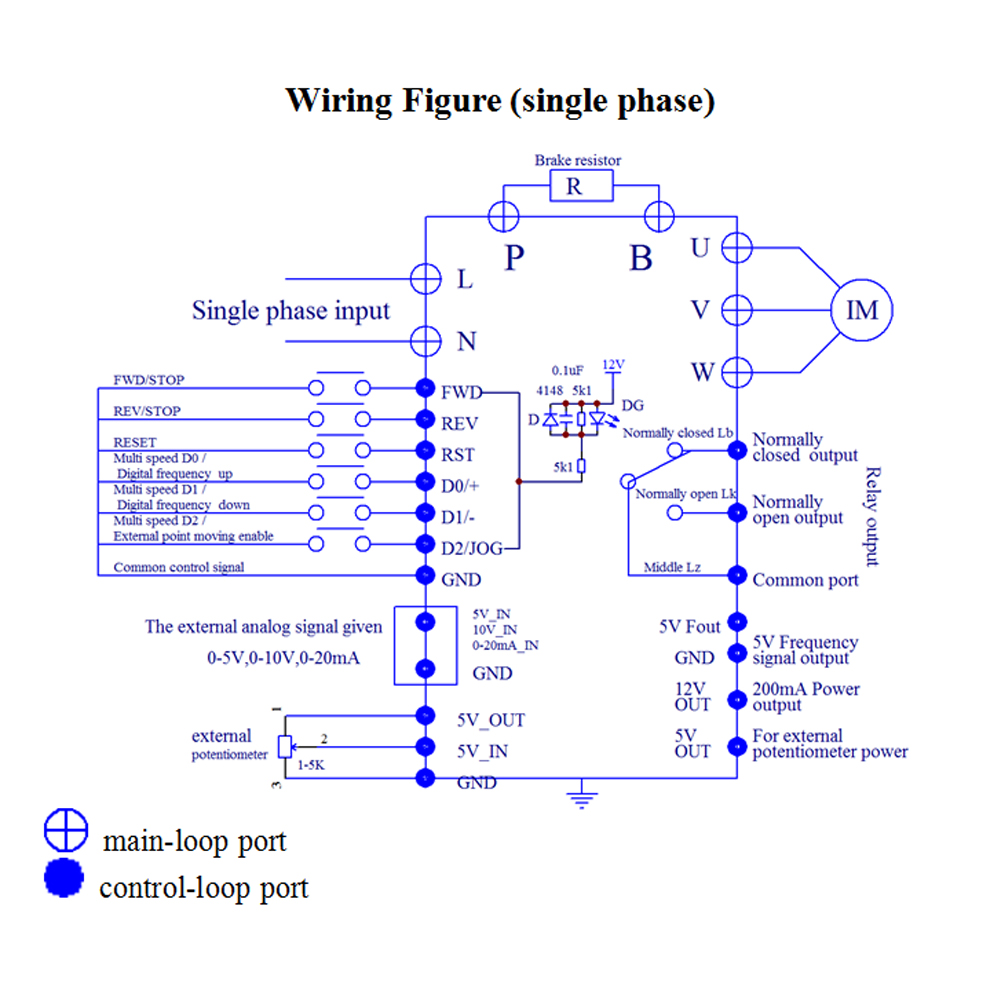

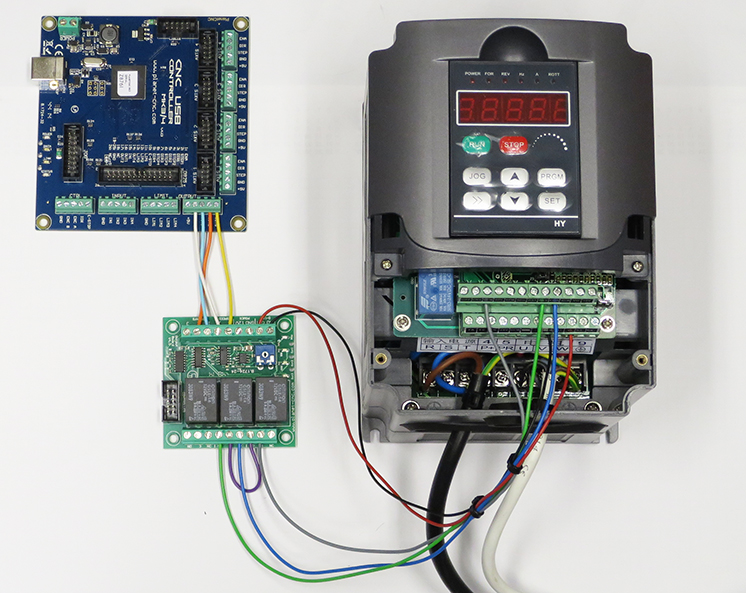

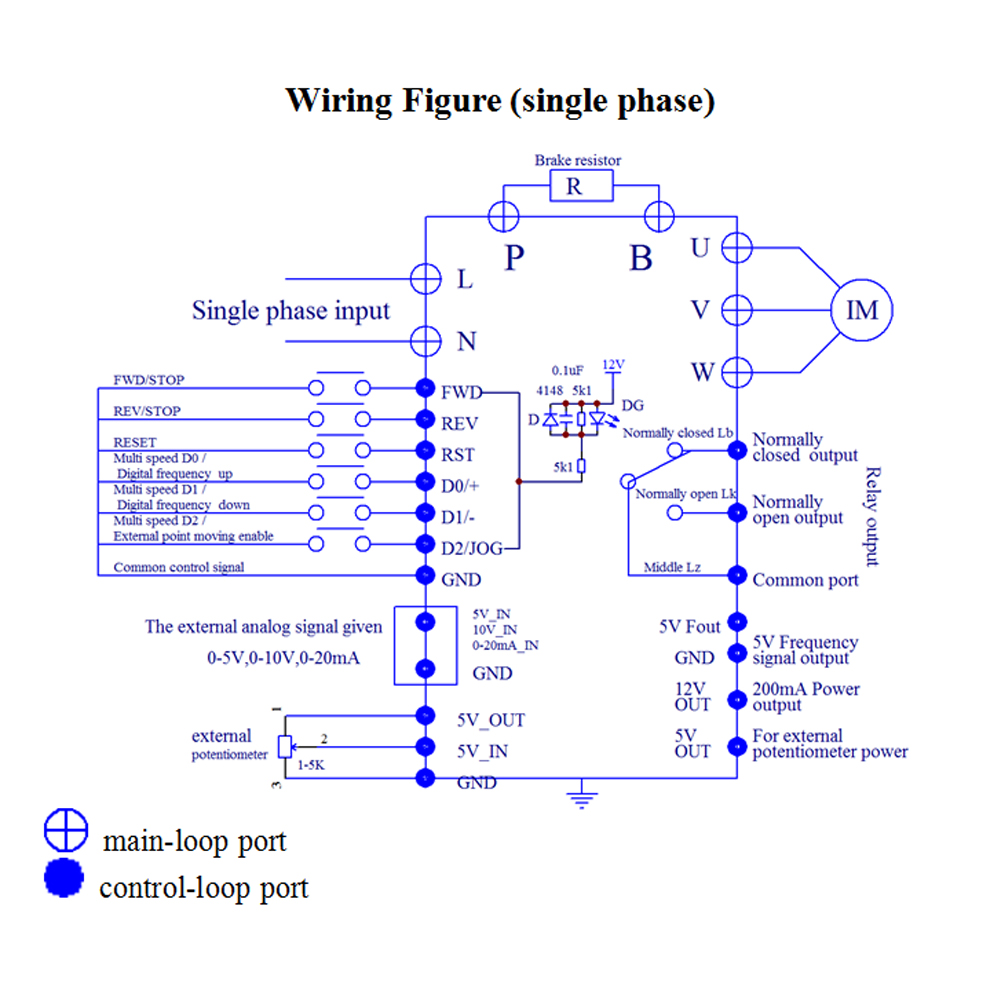

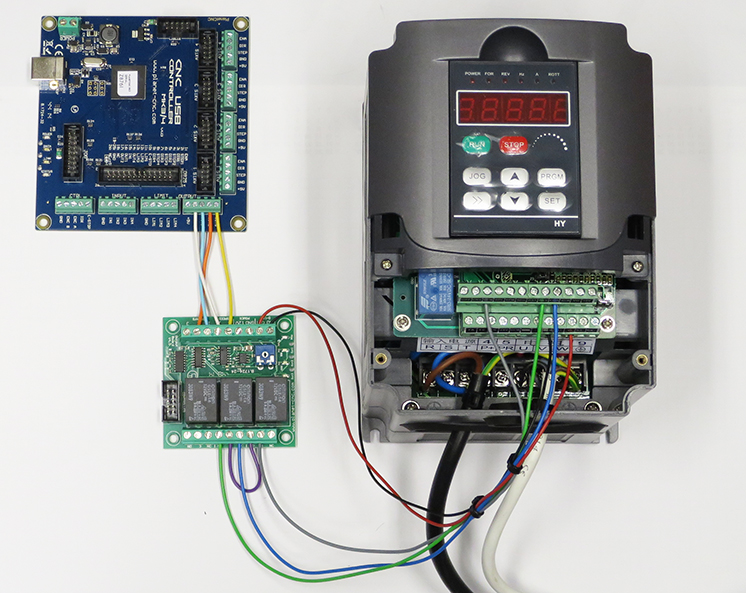

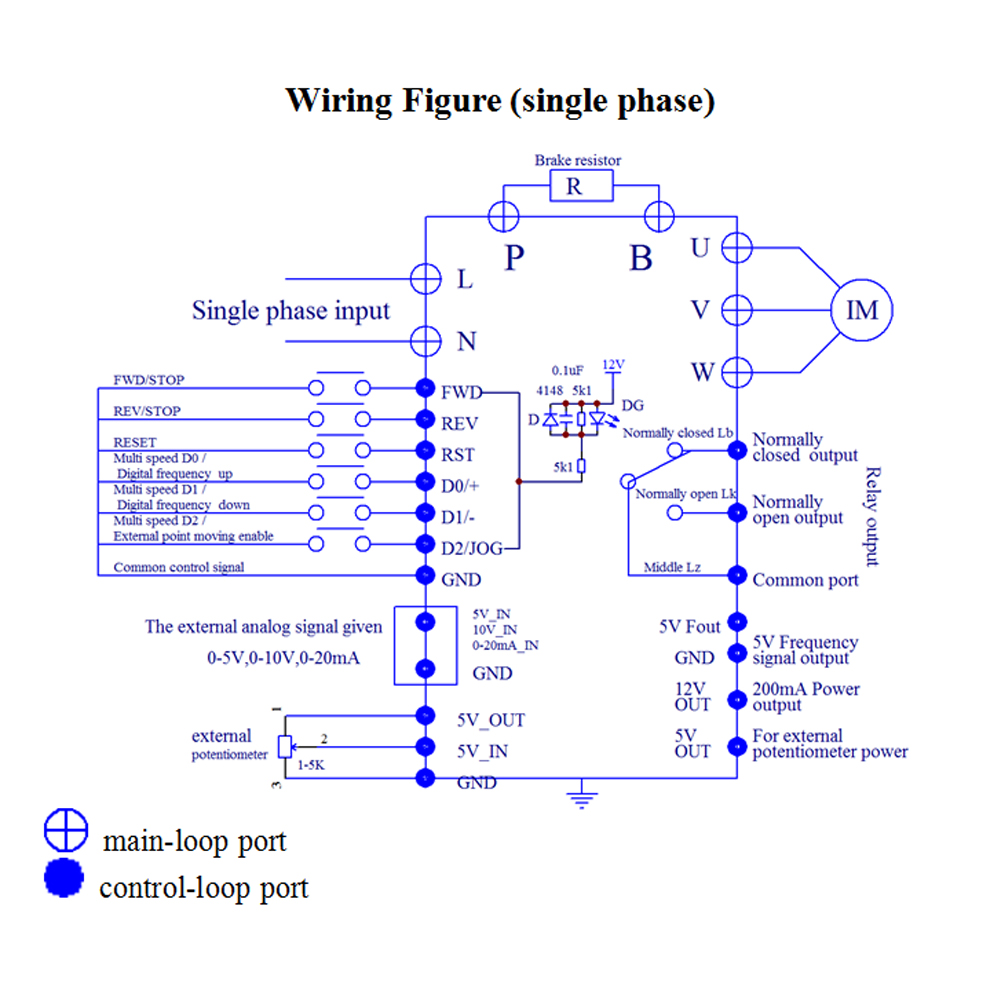

p vfd and motor terminals connection youtube 01 08 2016 vfd variable frequency drive used for 1 change speed of motor 3 phase 2 change direction of motor 3 do different function on motor operation like jog acce deacc time taking feed back up p p motor connection with vfd delta or wye gohz com 06 01 2017 motor connection with vfd delta or wye friday january 6 2017 for induction motors if you run the motor at a high flux level the winding flux magnetizing current has a significant third harmonic content that can flow around the delta winding without appearing in the lines to the vfd hy type 220v vfd connection spindle motor and setting video 19 11 2015 hy type 220v vfd connection spindle motor and setting video hy type 220v vfd connection spindle motor and setting video skip navigation 1 phase 220v to 3 phase 380v 5 5kw vfd inverter vfd wiring 1 main circuit wiring the vfd main circuit terminals shown as below figure 1 the vfd s three phase ac input terminals r l1 s l2 t l3 the power line s input terminals connect to 3 phase ac power through line protection or leakage protection breaker it does not need to consider the connection of phase sequence iet forums inverter and star connection an inverter drive is often a better alternative to star delta starting and also allows for speed control of the motor if the inverter is powered off a single phase supply it is more cost effective for it to produce a 240v phase to phase output the motor will therefore be matched with the characteristics of the inverter ups inverter wiring diagrams connection ups inverter wiring diagrams connection how to connect automatic ups inverter to the home supply system a complete note on solar panel installation calculation about no of solar panels batteries rating backup time inverter ups rating load and required watts with circuit diagrams p p variable frequency drive wikipedia a variable frequency drive is a device used in a drive system consisting of the following three main sub systems ac motor main drive controller assembly and drive operator interface 210 211 ac motor the ac electric motor used in a vfd system is usually a three phase induction motor products inverters ac motor drives delta group with modern power electronics and advanced microprocessor technology delta s ac motor drives are able to efficiently control motor speed improve machine automation and save energy taking advantage of our strong position in power electronics technology delta s vfd series of ac motor drives has evolved rapidly why choose delta over star connection for a 3 phase motor with a the maximum vfd output voltage rating is normally the same as the input power voltage rating what could be done with a vfd is to use the delta motor connection with a 415 v vfd but set the vfd to have an output of 240 v at 50 hz and 415 v at 86 hz jual inverter delta vfd022el21a 3hp 1 phase 220v delta inverter jual inverter delta vfd022el21a 3hp 1 phase 220v delta inverter vfd el dengan harga rp 4 210 000 dari toko online delta electric kota bekasi cari product komponen listrik lainnya di tokopedia jual beli online aman dan nyaman hanya di tokopedia vfd inverter search vfd inverter p p

p vfd and motor terminals connection youtube 01 08 2016 vfd variable frequency drive used for 1 change speed of motor 3 phase 2 change direction of motor 3 do different function on motor operation like jog acce deacc time taking feed back up p p motor connection with vfd delta or wye gohz com 06 01 2017 motor connection with vfd delta or wye friday january 6 2017 for induction motors if you run the motor at a high flux level the winding flux magnetizing current has a significant third harmonic content that can flow around the delta winding without appearing in the lines to the vfd hy type 220v vfd connection spindle motor and setting video 19 11 2015 hy type 220v vfd connection spindle motor and setting video hy type 220v vfd connection spindle motor and setting video skip navigation 1 phase 220v to 3 phase 380v 5 5kw vfd inverter vfd wiring 1 main circuit wiring the vfd main circuit terminals shown as below figure 1 the vfd s three phase ac input terminals r l1 s l2 t l3 the power line s input terminals connect to 3 phase ac power through line protection or leakage protection breaker it does not need to consider the connection of phase sequence iet forums inverter and star connection an inverter drive is often a better alternative to star delta starting and also allows for speed control of the motor if the inverter is powered off a single phase supply it is more cost effective for it to produce a 240v phase to phase output the motor will therefore be matched with the characteristics of the inverter ups inverter wiring diagrams connection ups inverter wiring diagrams connection how to connect automatic ups inverter to the home supply system a complete note on solar panel installation calculation about no of solar panels batteries rating backup time inverter ups rating load and required watts with circuit diagrams p p variable frequency drive wikipedia a variable frequency drive is a device used in a drive system consisting of the following three main sub systems ac motor main drive controller assembly and drive operator interface 210 211 ac motor the ac electric motor used in a vfd system is usually a three phase induction motor products inverters ac motor drives delta group with modern power electronics and advanced microprocessor technology delta s ac motor drives are able to efficiently control motor speed improve machine automation and save energy taking advantage of our strong position in power electronics technology delta s vfd series of ac motor drives has evolved rapidly why choose delta over star connection for a 3 phase motor with a the maximum vfd output voltage rating is normally the same as the input power voltage rating what could be done with a vfd is to use the delta motor connection with a 415 v vfd but set the vfd to have an output of 240 v at 50 hz and 415 v at 86 hz jual inverter delta vfd022el21a 3hp 1 phase 220v delta inverter jual inverter delta vfd022el21a 3hp 1 phase 220v delta inverter vfd el dengan harga rp 4 210 000 dari toko online delta electric kota bekasi cari product komponen listrik lainnya di tokopedia jual beli online aman dan nyaman hanya di tokopedia vfd inverter search vfd inverter p p

p vfd and motor terminals connection youtube 01 08 2016 vfd variable frequency drive used for 1 change speed of motor 3 phase 2 change direction of motor 3 do different function on motor operation like jog acce deacc time taking feed back up p p motor connection with vfd delta or wye gohz com 06 01 2017 motor connection with vfd delta or wye friday january 6 2017 for induction motors if you run the motor at a high flux level the winding flux magnetizing current has a significant third harmonic content that can flow around the delta winding without appearing in the lines to the vfd hy type 220v vfd connection spindle motor and setting video 19 11 2015 hy type 220v vfd connection spindle motor and setting video hy type 220v vfd connection spindle motor and setting video skip navigation 1 phase 220v to 3 phase 380v 5 5kw vfd inverter vfd wiring 1 main circuit wiring the vfd main circuit terminals shown as below figure 1 the vfd s three phase ac input terminals r l1 s l2 t l3 the power line s input terminals connect to 3 phase ac power through line protection or leakage protection breaker it does not need to consider the connection of phase sequence iet forums inverter and star connection an inverter drive is often a better alternative to star delta starting and also allows for speed control of the motor if the inverter is powered off a single phase supply it is more cost effective for it to produce a 240v phase to phase output the motor will therefore be matched with the characteristics of the inverter ups inverter wiring diagrams connection ups inverter wiring diagrams connection how to connect automatic ups inverter to the home supply system a complete note on solar panel installation calculation about no of solar panels batteries rating backup time inverter ups rating load and required watts with circuit diagrams p p variable frequency drive wikipedia a variable frequency drive is a device used in a drive system consisting of the following three main sub systems ac motor main drive controller assembly and drive operator interface 210 211 ac motor the ac electric motor used in a vfd system is usually a three phase induction motor products inverters ac motor drives delta group with modern power electronics and advanced microprocessor technology delta s ac motor drives are able to efficiently control motor speed improve machine automation and save energy taking advantage of our strong position in power electronics technology delta s vfd series of ac motor drives has evolved rapidly why choose delta over star connection for a 3 phase motor with a the maximum vfd output voltage rating is normally the same as the input power voltage rating what could be done with a vfd is to use the delta motor connection with a 415 v vfd but set the vfd to have an output of 240 v at 50 hz and 415 v at 86 hz jual inverter delta vfd022el21a 3hp 1 phase 220v delta inverter jual inverter delta vfd022el21a 3hp 1 phase 220v delta inverter vfd el dengan harga rp 4 210 000 dari toko online delta electric kota bekasi cari product komponen listrik lainnya di tokopedia jual beli online aman dan nyaman hanya di tokopedia vfd inverter search vfd inverter p p

inverter adalah,inverter ac,inverter ac adalah,inverter ac ke dc,inverter aki,inverter ac to dc,inverter abb,inverter artinya,inverter ac ke ac,inverter aki motor,vfd adalah,vfd a series of unfortunate events,vfd applications,vfd abb,vfd asoue,vfd acronym,vfd advantages,vfd allen bradley,vfd abbreviation,vfd arduino,connection artinya,connection adalah,connection are available,connection alfamart,connection academy,connection antonym,connections academy login,connection apartments,connection abbreviation,connection at auburn