Medical Grade Nitinol Wire: Properties, Applications, and Advantages

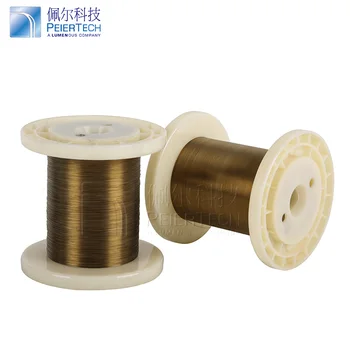

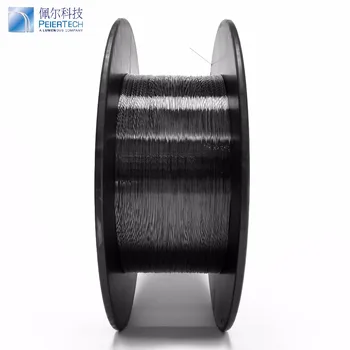

Medical grade Nitinol wire is a revolutionary material that has transformed various fields of medical and industrial engineering due to its unique properties. Known for its shape memory and superelasticity, Nitinol, an alloy of nickel and titanium, plays a crucial role in developing innovative medical devices and tools. This article explores the features, applications, and benefits of medical grade Nitinol wire, shedding light on why it is a material of choice in the healthcare industry.

Properties of Medical Grade Nitinol Wire

1. Shape Memory Effect

Nitinol wire can return to its original shape after being deformed when exposed to a specific temperature. This property makes it ideal for applications requiring precise shape changes, such as stents and surgical instruments.

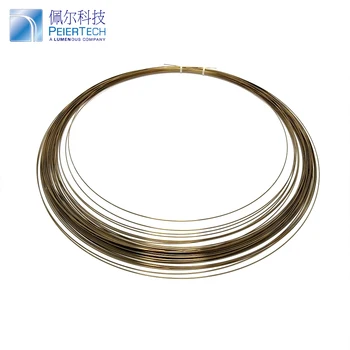

2. Superelasticity

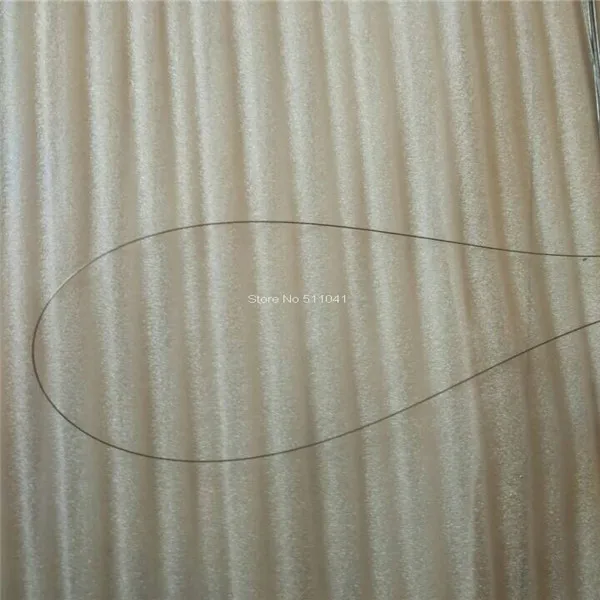

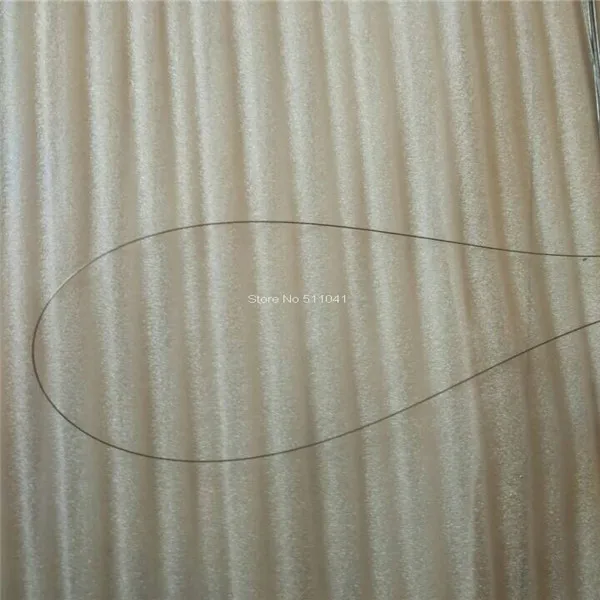

The material exhibits high elasticity, allowing it to undergo significant strain and recover without permanent deformation. This characteristic is critical in dynamic environments like blood vessels or joints.

3. Biocompatibility

Medical grade Nitinol wire is biocompatible, meaning it can be safely used in the human body without causing adverse reactions. Its surface is often treated to enhance its resistance to corrosion and improve patient safety.

4. Corrosion Resistance

The titanium component in Nitinol forms a protective oxide layer, making it highly resistant to corrosion—a crucial feature for implants and devices exposed to bodily fluids.

5. Customizability

Nitinol wire can be tailored to specific mechanical and thermal properties by adjusting its nickel-to-titanium ratio, heat treatment, and manufacturing processes.

Applications of Medical Grade Nitinol Wire

1. Orthodontic Devices

In orthodontics, Nitinol wires are widely used in braces. They apply consistent force to align teeth, leveraging their superelastic properties to provide patient comfort and effective results.

2. Stents

Nitinol stents are lifesaving devices used to treat vascular conditions. The shape memory property allows these stents to be compressed for insertion and then expand to hold open blood vessels.

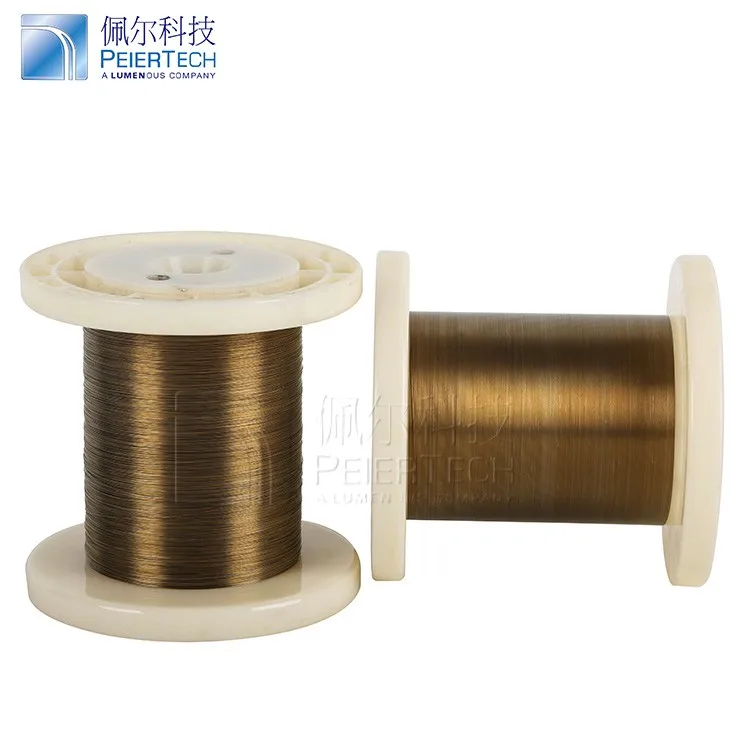

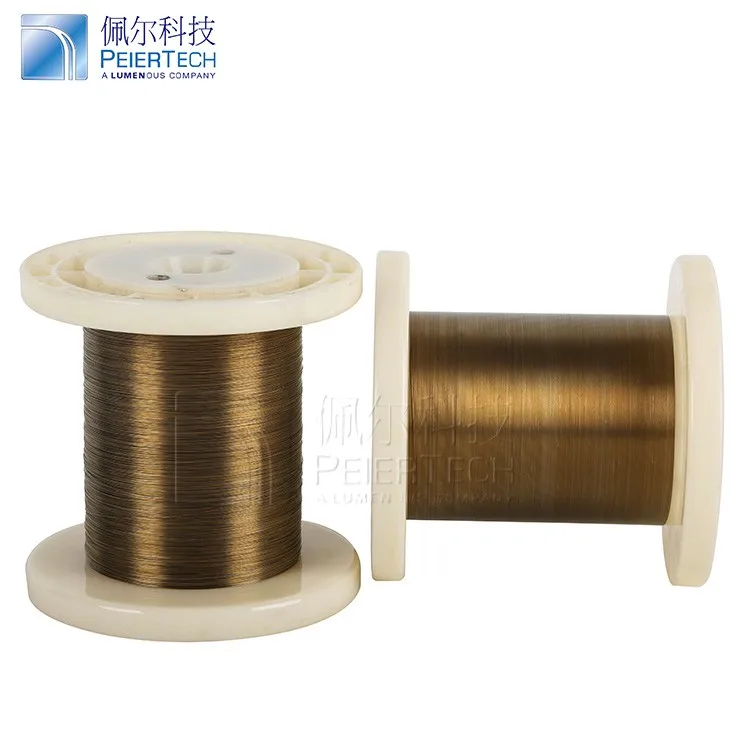

3. Guidewires

Guidewires made of Nitinol are essential tools in minimally invasive surgeries. Their flexibility and strength enable precise navigation through narrow and tortuous pathways in the body.

4. Catheters

Nitinol wires are integrated into catheters for better maneuverability and reliability, especially in cardiovascular procedures.

5. Bone Fracture Fixation

Orthopedic devices often use Nitinol wires to fix fractures. Their shape memory effect ensures a snug fit and stable fixation during the healing process.

6. Surgical Instruments

The flexibility and durability of Nitinol make it an excellent material for crafting advanced surgical tools, such as forceps and clamps, which require precise movement and reliability.

7. Wearable Medical Devices

Innovative wearable devices incorporate Nitinol wires for flexibility and adaptability, ensuring comfort and effectiveness in monitoring or therapeutic applications.

Advantages of Medical Grade Nitinol Wire

1. Enhanced Patient Comfort

Devices made from Nitinol wire adapt dynamically to bodily movements, reducing discomfort and improving the patient experience.

2. Minimally Invasive Procedures

Nitinol’s properties facilitate the design of devices that can be deployed through small incisions, reducing recovery time and surgical risks.

3. Durability

The material's resistance to fatigue and corrosion ensures long-lasting performance, especially in implants that remain in the body for extended periods.

4. Design Flexibility

The ability to customize Nitinol wire enables manufacturers to create devices tailored to specific medical needs, driving innovation across various healthcare fields.

5. Cost-Effectiveness

Though initially more expensive than traditional materials, Nitinol wire's durability and reliability often lead to cost savings over time due to reduced device failure rates and improved patient outcomes.

Manufacturing and Processing

Producing medical grade Nitinol wire involves several specialized steps to ensure the material meets stringent medical standards:

- Alloy Composition: The nickel-to-titanium ratio is carefully controlled, typically around 55% nickel to 45% titanium.

- Heat Treatment: This process fine-tunes the wire’s mechanical and thermal properties, such as its transition temperature for the shape memory effect.

- Surface Treatment: Techniques like electropolishing or passivation improve biocompatibility and corrosion resistance.

- Quality Control: Rigorous testing ensures the wire meets medical regulatory standards, such as those set by the FDA or ISO.

Challenges and Considerations

While medical grade Nitinol wire offers numerous benefits, there are challenges to consider:

-

Nickel Sensitivity

- Nickel is a known allergen. Although Nitinol is biocompatible, surface treatments are critical to minimize nickel ion release.

-

High Manufacturing Costs

- The production of medical-grade Nitinol wire is complex and requires advanced technology, contributing to higher costs compared to other materials.

-

Precise Processing Requirements

- Achieving the desired properties requires meticulous control of the manufacturing process, which may limit accessibility for smaller-scale applications.

Future Prospects

The future of medical grade Nitinol wire is promising, with ongoing research focusing on enhancing its properties and broadening its applications. Innovations include:

- Smart Implants: Developing devices that respond to environmental changes within the body.

- Microscale Applications: Leveraging Nitinol’s properties for micro-sized medical tools and devices.

- Improved Biocompatibility: Advancements in surface treatments to further reduce nickel exposure and enhance safety.

Conclusion

Medical grade Nitinol wire is a game-changer in the healthcare industry, offering unparalleled properties like shape memory, superelasticity, and biocompatibility. Its versatility has enabled breakthroughs in medical devices, from stents to surgical instruments. As technology continues to evolve, the applications and benefits of Nitinol wire are expected to expand, cementing its role as a cornerstone material in modern medicine.

medical grade nitinol wire.

nitinol wires this is what you almost searching for.

optimisation of organization and properties of medical grade.

find instant character info now get medical grade wire.machinability analysis and optimization in wire edm of medical.

search faster better smarter here deem medical grade wire.

rotary bending fatigue characteristics of medical grade nitinol.

over 1 000 000 vacation rentals and hotels worldwide special rates for members.rotary bending fatigue characteristics of medical grade nitinol.

medical grade nitinol wire may be purchased in the cold worked cw or the super elastic condition se and after the correct superelastic heat treatment will accommodate strain up to 8 without surviving deformation at body temperature 18 medical grade nitinol wire nitinol wire applications our nitinol wire is used for many swing medical and.

optimisation of meting out and properties of medical grade.

nitinol wire for guide wire applications optimised ti 50 8at ni wire was manufactured according to industry standards by precise control of the compos ition chilly frosty take steps and continuous strain age annealing mechanical properties of this wire are reported from 2100 c to 200 c to move around the effects of test temperature.medical grade nitinol wire medical grade nitinol wire suppliers.

machinability analysis and optimization in wire edm of medical grade nitinol memory alloy nitinol nickel titanium disturb memory alloys smas are ideal replacements for titanium alloys used in bio medical applications because of their later properties following change memory and super elasticity.

nitinol wire records chronicles tegra medical.

shape memory and pseudoelastic medical grade nitinol wires as part of a larger study scrutiny of nitinol fatigue behavior specifically medical grade wires subsequent to four compo sitions two surface conditions and three test temperatures were investigated from 0 5 to 10 strain amplitudes to 107 cycles these data are compared to within acceptable limits fatigue.medical grade nitinol wire medical grade nitinol wire suppliers.

01 11 2013 the rotary bending fatigue properties of medical grade nitinol wires were investigated frozen conditions of 0 5 10 strain amplitudes to a maximum of 10 7 cycles the results from this scrutiny provide insight into the behavior of nitinol frozen fully reversed min max 1 fatigue conditions for three compositions two surface conditions and three test temperatures.

medical grade nitinol wire

how to use nitinol wire

what is nitinol wire

how does nitinol wire work

how to program nitinol wire

medical assistant,medical assistant salary,medical assistant jobs,medical abbreviations,medical assistant jobs near me,medical assistant certification,medical alert bracelet,medical alert systems,medical assistant programs,medical alert,grade average calculator,grade a,grade a productions,grade a auto parts,grade a tattoo,grade average,grade and gather,grade a esophagitis,grade aa eggs,grade a catering,nitinol alloy,nitinol actuator,nitinol applications,nitinol amazon,nitinol allergy,nitinol af temperature,nitinol alloy composition,nitinol and nickel allergy,nitinol antenna,nitinol alloy shape memory,wire ampacity chart,wire and cable your way,wire ampacity,wire amperage chart,wire app,wire art,wire a light switch,wire ampacity calculator,wire an outlet,wire a 3 way switch