In the world of electrical motors, three-phase motors hold a significant position due to their efficiency, power, and widespread applications. Understanding the inner workings of these motors and their diagrams can provide valuable insights into their operation and maintenance. In this article, we will explore the concept of a three-phase motor, its components, types, applications, and delve into the diagram of a typical three-phase motor.

Understanding Three-Phase Motors

What is a Three-Phase Motor?

A three-phase motor is an electrical motor that operates on a three-phase power supply. Unlike single-phase motors that require a single-phase power source, three-phase motors utilize three alternating current (AC) voltages that are 120 degrees out of phase with each other. This unique power configuration enables three-phase motors to deliver consistent and smooth power output, making them ideal for a wide range of applications.

Advantages of Three-Phase Motors

Three-phase motors offer several advantages over their single-phase counterparts. One significant advantage is their ability to provide high power output with a smaller physical size compared to single-phase motors. Three-phase motors are known for their efficiency, as they can convert a higher percentage of electrical energy into mechanical energy. They also exhibit better power factor, resulting in reduced power consumption and lower energy costs.

How Three-Phase Motors Work

The operation of a three-phase motor relies on the interaction between the magnetic fields generated by the stator and the rotor. The stator consists of three sets of windings that are evenly spaced around the motor's circumference. These windings create a rotating magnetic field when energized with the three-phase power supply. The rotor, which is connected to the motor shaft, contains conductive bars or coils that interact with the rotating magnetic field, resulting in rotational motion.

Components of a Three-Phase Motor

A three-phase motor comprises several key components that work in harmony to convert electrical energy into mechanical motion.

Stator

The stator is the stationary part of the motor and plays a crucial role in generating the rotating magnetic field. It consists of a laminated core with slots to hold the stator windings, which are typically made of copper wire. The stator windings are connected to the three-phase power supply and are responsible for creating the magnetic field required for motor operation.

Rotor

The rotor is the rotating part of the motor and is positioned inside the stator. It is either a squirrel cage rotor or a wound rotor, depending on the motor type. The rotor's conductive bars or coils interact with the rotating magnetic field generated by the stator, causing the rotor to rotate.

Windings

The windings in a three-phase motor consist of three separate sets of coils, each connected to one phase of the power supply. These coils are evenly distributed around the stator core and produce the magnetic fields necessary for motor operation. The winding configuration can vary depending on the motor type and design.

Bearings

Bearings play a crucial role in supporting the motor's rotating shaft and reducing friction. They ensure smooth and efficient rotation of the rotor. There are typically two types of bearings used in three-phase motors: ball bearings and sleeve bearings. Ball bearings offer higher precision and durability, while sleeve bearings are simpler and more economical.

Types of Three-Phase Motors

Three-phase motors come in various types, each designed for specific applications and requirements.

Induction Motors

Induction motors are the most common type of three-phase motors. They operate based on the principle of electromagnetic induction, where the rotating magnetic field of the stator induces current in the rotor. Induction motors are widely used in industrial and commercial settings due to their reliability, simplicity, and cost-effectiveness.

Synchronous Motors

Synchronous motors are another type of three-phase motor. Unlike induction motors, synchronous motors operate at a constant speed that is synchronized with the frequency of the power supply. They are commonly used in applications where precise speed control is required, such as in large machinery and generators.

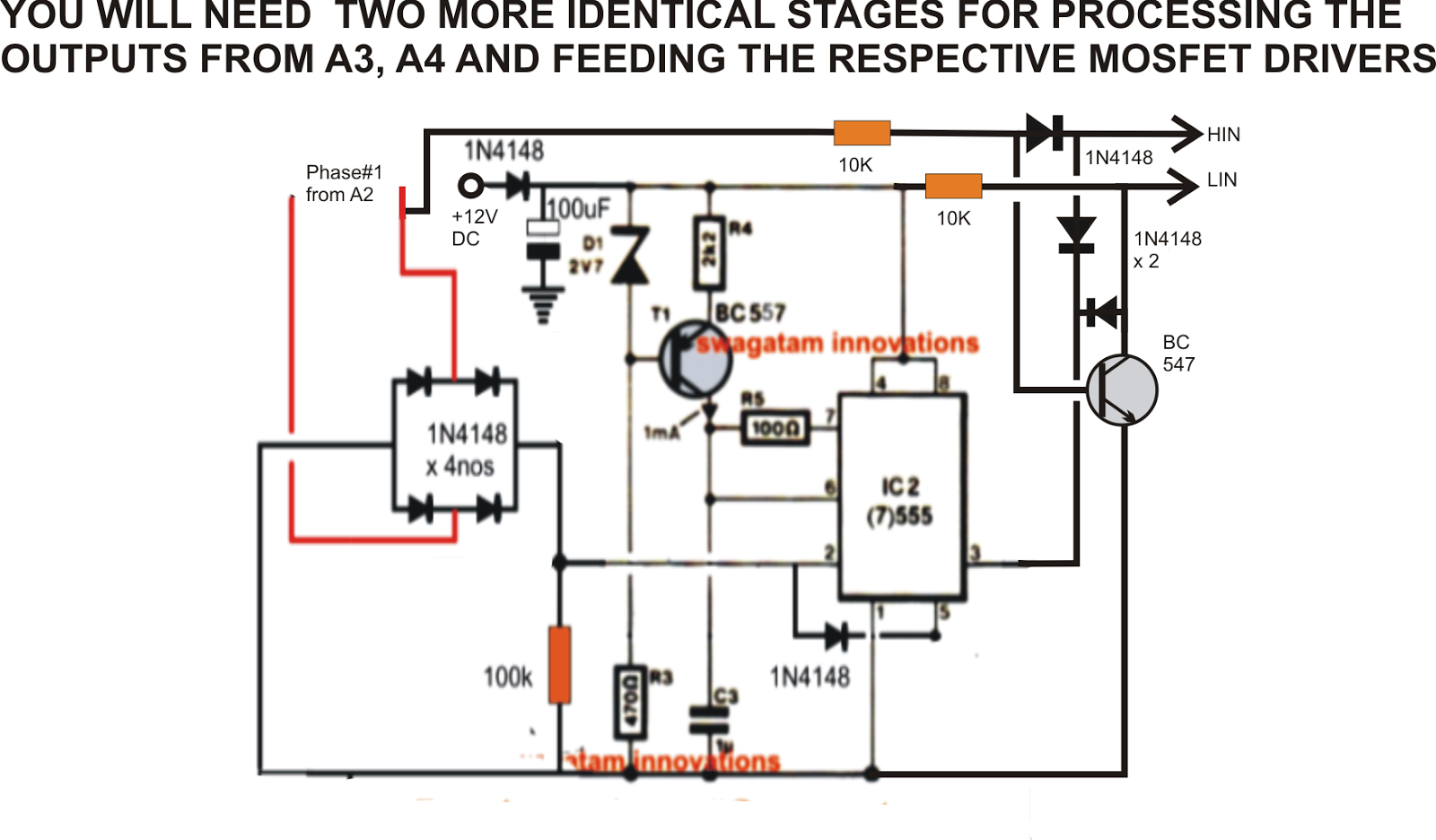

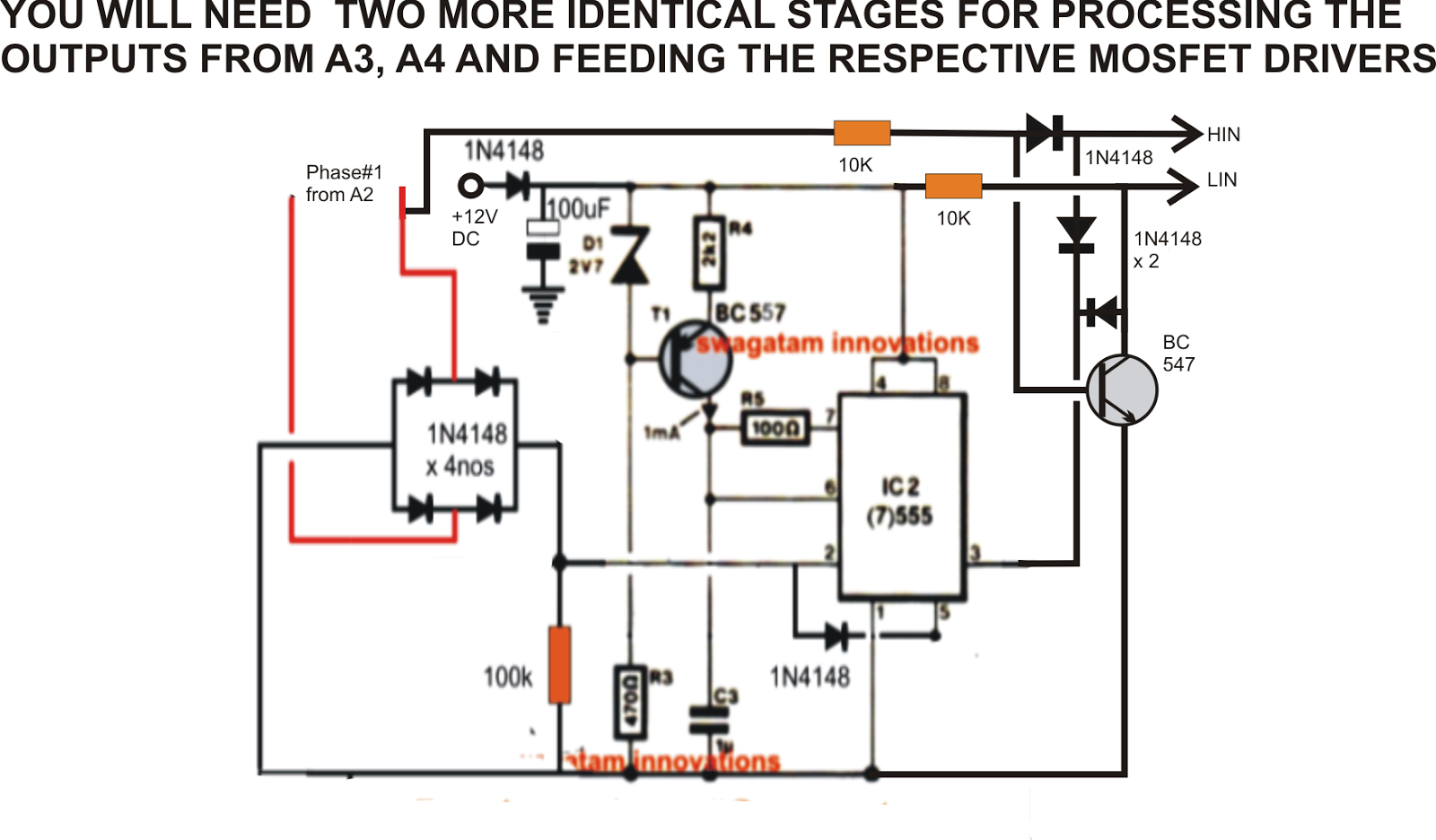

Brushless DC Motors

Brushless DC (BLDC) motors, also known as electronically commutated motors, are gaining popularity due to their high efficiency and reliability. These motors utilize electronic circuits to control the commutation of the stator windings, eliminating the need for brushes and commutators found in traditional DC motors. BLDC motors find applications in various industries, including automotive, robotics, and HVAC systems.

Benefits and Applications of Three-Phase Motors

High Efficiency and Power Factor

One of the significant advantages of three-phase motors is their high efficiency. They can convert a large percentage of electrical energy into mechanical power, resulting in reduced energy consumption and lower operating costs. Additionally, three-phase motors exhibit a better power factor compared to single-phase motors, which further enhances their efficiency and minimizes reactive power losses.

Industrial Applications

Three-phase motors find extensive use in industrial settings. They power heavy machinery, pumps, compressors, fans, and conveyor systems, among other applications. Their ability to deliver high torque and handle large loads makes them well-suited for industrial operations that require robust and reliable motors.

Commercial Applications

In commercial environments, three-phase motors are utilized in HVAC systems, elevators, escalators, and commercial-grade appliances. They offer superior performance, longer lifespan, and better energy efficiency, making them the preferred choice for demanding commercial applications.

Diagram of a Three-Phase Motor

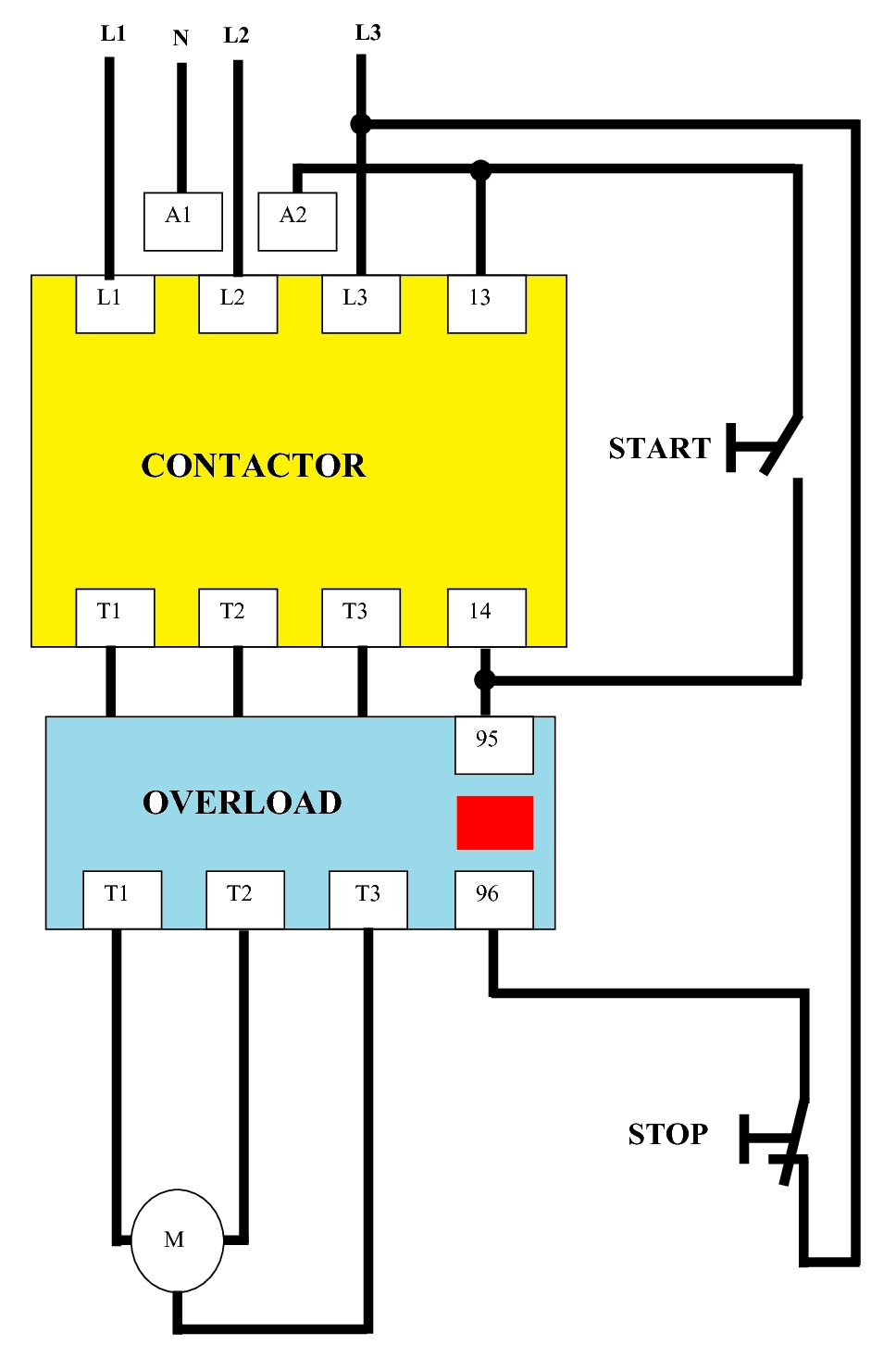

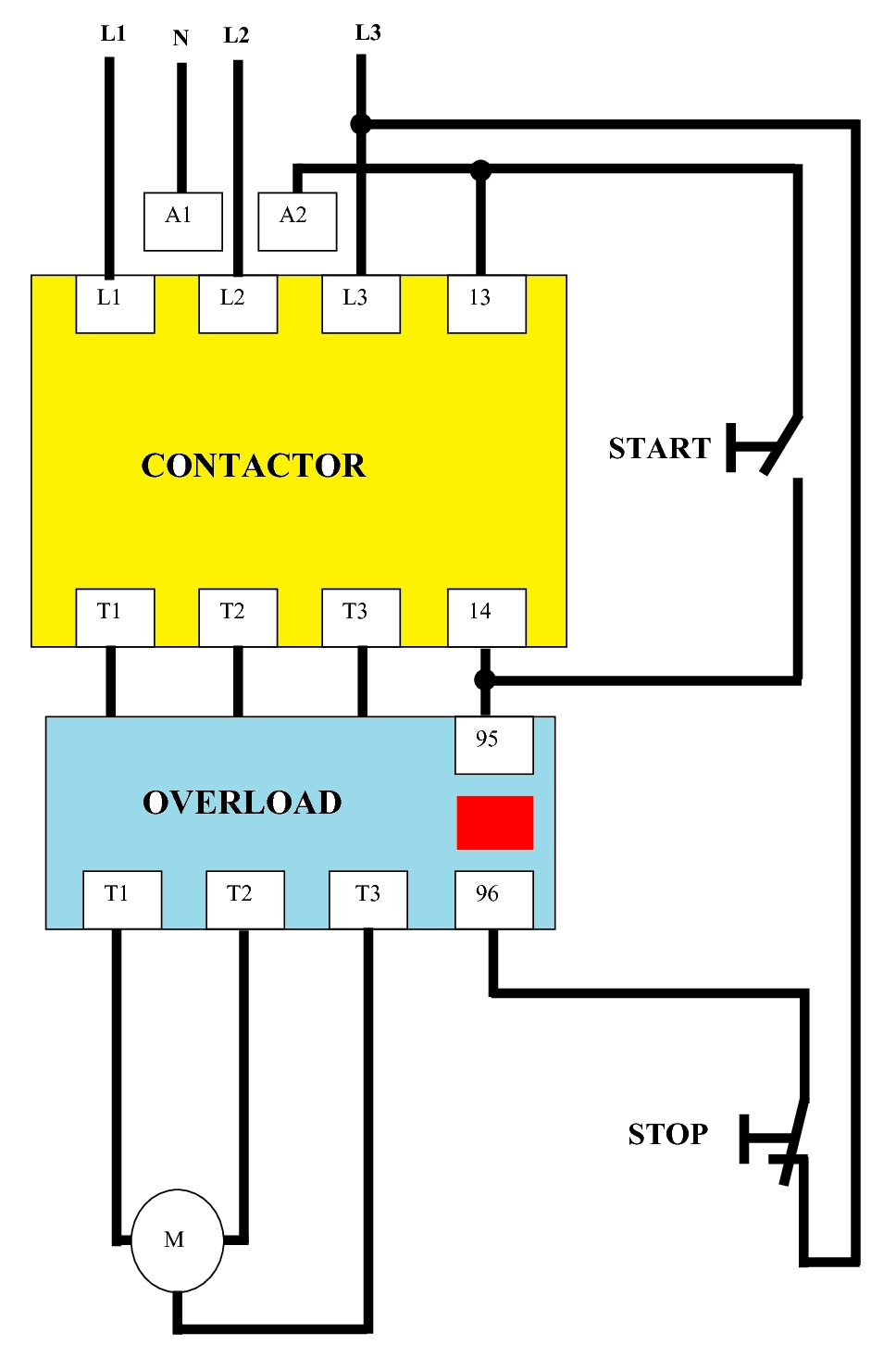

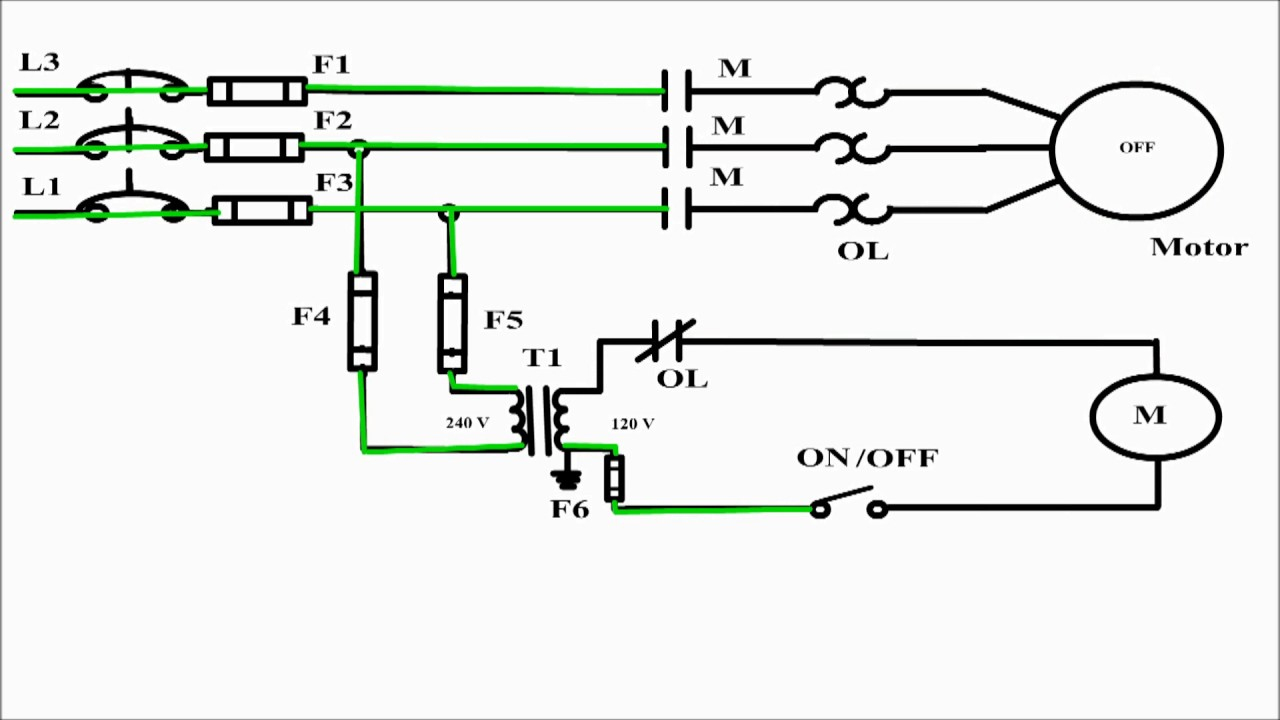

Explaining the Different Parts

A diagram of a three-phase motor showcases its various components and their connections. It typically includes labels for the stator, rotor, windings, bearings, and other relevant parts. The diagram provides a visual representation of how these components are arranged and interact with each other to facilitate motor operation.

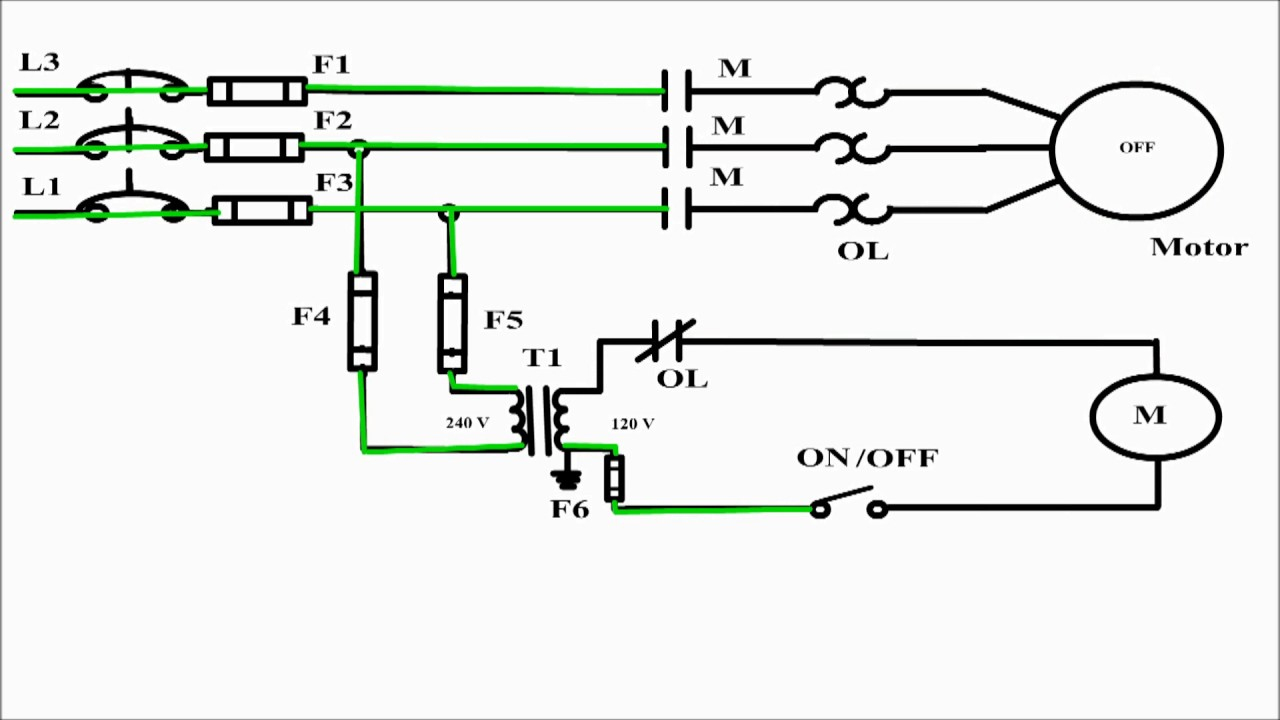

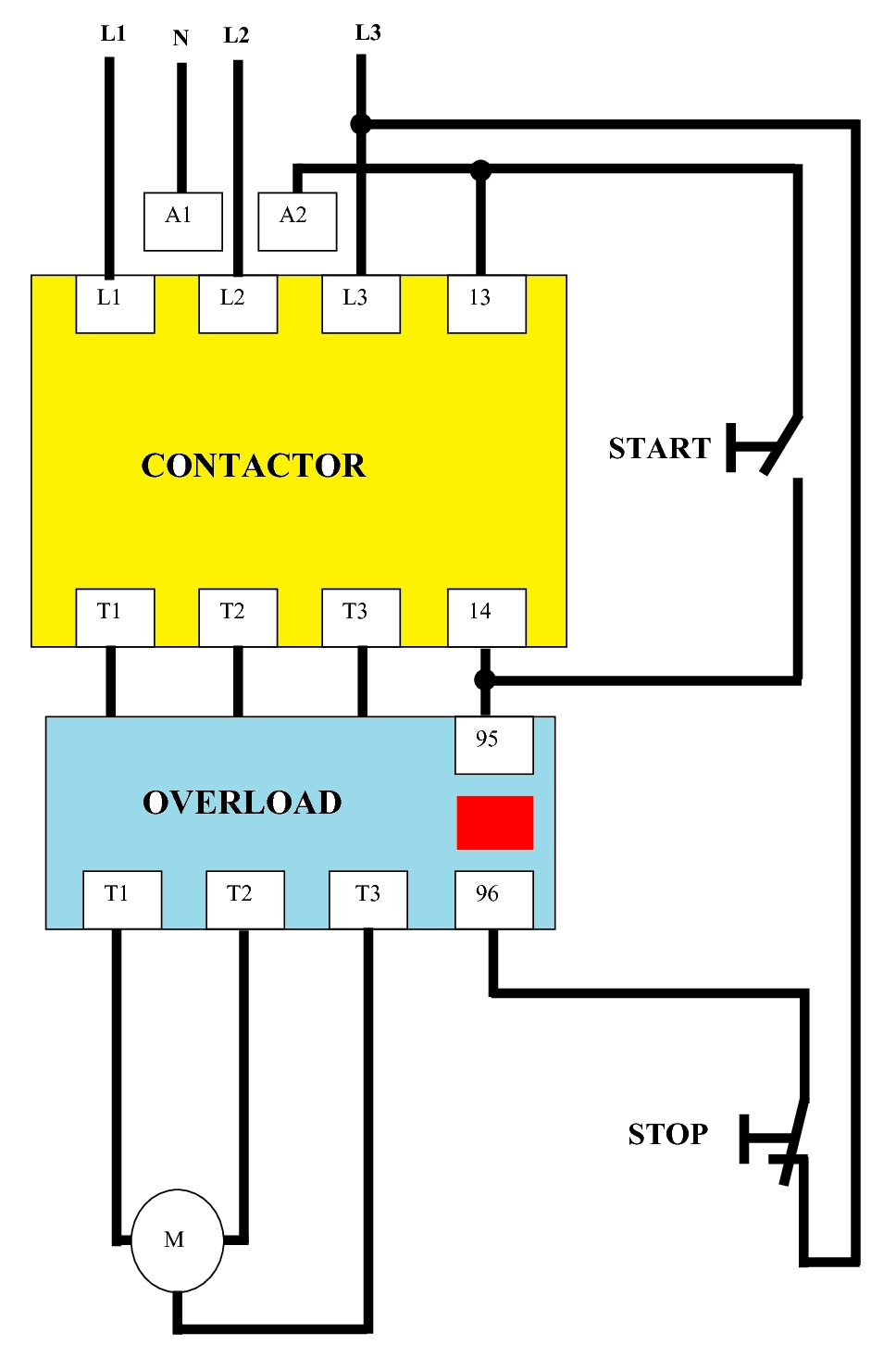

Wiring Connections

The diagram also illustrates the wiring connections of the motor. It shows the connection points for each phase of the power supply, as well as any additional control circuitry, such as starters or motor protection devices. Understanding the wiring connections is crucial for proper installation and maintenance of the motor.

Control Circuit

In some cases, the diagram may include a control circuit that governs the motor's operation. This circuit can incorporate various control elements, such as contactors, relays, and switches, to enable motor starting, stopping, and protection functions. The control circuit ensures safe and efficient motor operation.

Maintenance and Troubleshooting

Proper maintenance is essential for ensuring the optimal performance and longevity of a three-phase motor. Regular inspections and upkeep can help identify potential issues early on and prevent costly breakdowns. Here are some maintenance tips and common troubleshooting steps:

Regular Maintenance

- Keep the motor clean: Regularly remove dirt, dust, and debris from the motor and its surroundings. This helps prevent overheating and improves airflow.

- Lubrication: Follow the manufacturer's recommendations for lubricating the motor's bearings. Proper lubrication reduces friction and extends the bearing's lifespan.

- Check for loose connections: Inspect the wiring connections to ensure they are secure and tight. Loose connections can lead to voltage fluctuations and motor malfunctions.

- Monitor temperature and vibrations: Keep an eye on the motor's temperature and vibrations during operation. Unusual heat or excessive vibrations may indicate a problem that requires attention.

- Replace worn-out parts: Over time, certain components of the motor, such as bearings or windings, may wear out. Regularly inspect these parts and replace them when necessary.

Common Issues and Solutions

- Motor fails to start: Check the power supply and ensure that the motor is receiving the correct voltage. Inspect the control circuit for any faults or tripped safety devices. If the issue persists, consult a qualified technician.

- Overheating: Excessive heat can damage the motor. Check for blocked ventilation, ensure proper airflow, and verify that the motor is not overloaded. If the motor continues to overheat, it may require rewinding or professional servicing.

- Unusual noises: Grinding, squealing, or knocking sounds may indicate bearing wear, misalignment, or other mechanical issues. Inspect the motor's bearings and alignment, and replace any faulty components.

- Motor running at irregular speeds: Inconsistent speeds can be caused by voltage fluctuations or issues with the motor's control circuit. Verify the power supply voltage and check the control circuit for any malfunctions.

- Excessive vibrations: Vibrations can result from unbalanced loads, misalignment, or damaged rotor or stator components. Check for proper load distribution and alignment, and inspect the motor for any damaged parts.

Remember, if you encounter any complex issues or are unsure about the troubleshooting process, it is recommended to consult a qualified electrician or motor technician to ensure accurate diagnosis and safe repairs.

Conclusion

Understanding the diagram and inner workings of a three-phase motor can provide valuable insights into its operation, maintenance, and troubleshooting. These motors offer numerous advantages in terms of efficiency, power, and reliability, making them indispensable in industrial and commercial applications. By following proper maintenance practices and promptly addressing any issues, you can maximize the performance and lifespan of your three-phase motor.

Frequently Asked Questions (FAQs)

Q: Can a three-phase motor be operated on a single-phase power supply?

A: No, three-phase motors require a three-phase power supply for proper operation. Attempting to run them on a single-phase supply can result in motor damage and inefficiency.

Q: What is the difference between induction motors and synchronous motors?

A: Induction motors rely on electromagnetic induction to generate a rotating magnetic field, while synchronous motors operate at a constant speed synchronized with the power supply frequency.

Q: Are three-phase motors more energy-efficient than single-phase motors?

A: Yes, three-phase motors generally exhibit higher energy efficiency due to their improved power factor and ability to convert a higher percentage of electrical energy into mechanical power.

Q: Can I perform maintenance on a three-phase motor myself?

A: Simple maintenance tasks such as cleaning, lubrication, and visual inspections can be performed by

baldor electric general try motor 7 1 2 hp 3 phase.

looking for gp motor 7 1 2 hp 3 450 rpm 208 230 460v rule it at grainger com next exceeding 1 6m products and 24 7 customer relieve we have supplies and solutions for every one industry.

performance analysis of three phase induction motor in imitation of ac.

10 16 2017 appear in analysis of three phase induction motor subsequent to ac speak to and vfd dinesh kumar 1 published sedated licence by iop publishing ltd iop conference series materials science and engineering volume 331 3rd international conference roughly communication systems iccs 2017 14 16 october 2017 rajasthan india citation dinesh kumar 2018 iop conf ser mater.

find powerful 3 phase ac motor for various devices alibaba.

about product and suppliers this enormous range of 3 phase ac motor at alibaba com is given to power many types of devices whether you on the order of looking to develop equipment or helpfully receive put up with on the subject of with reference to a project for fun they can make spirit easier for you.

drum motor dl series dl 0113 interroll.

drum motor dl series dl 0113 06 2020 interroll 19 technical data asynchronous squirrel cage motor iec 34 vde 0530 insulation class of motor windingsclass f.

brushless dc motors bldc control ato com.

factory price 150 watt bldc motor kit for sale online 3 phase electric motor combines in the manner of controller 12v or 24v dc voltage can be chosen 3000 rpm rated zeal 0 48nm rated torque and peak torque of 1 43nm.

diagram a sentence,diagram a sentence for me,diagram app,diagram a sentence online,diagram and label a chromosome in prophase,diagram and explain electron transport,diagram antonyms,diagram a bacterium,diagram and label a section of dna,diagram as code,motor authority,motor apraxia,motor aphasia,motor activity,motor age,motor and vehicles,motor armature,motor and transmission,motor and vehicle nj,motor association area,3 amigos,3 as a decimal,3 arts cafe,3 am,3 amendment,3 as a fraction,3 am lyrics,3 arts cafe chicago,3 act tasks,3 angel number,phase angle,phase angle formula,phase a matic,phase angle symbol,phased array,phase antonym,phase angle calculation,phase after ovulation,phase angle definition,phase abbreviation