Cummins Starter Wiring Diagram

What is a Cummins Starter?

Understanding the Wiring Diagram

Components of a Cummins Starter

- Armature: The armature is the rotating part of the starter that carries the electrical current, converting it into mechanical force to crank the engine.

- Field Coils: The field coils create a magnetic field when an electric current flows through them. This magnetic field interacts with the armature, causing it to rotate.

- Solenoid: The solenoid is an electromechanical switch that connects the starter to the battery and ignition switch. It engages the starter motor when the ignition key is turned, allowing the current to flow to the armature.

- Drive Gear: The drive gear is the component that engages with the engine's flywheel, transmitting the rotational force from the starter to the engine.

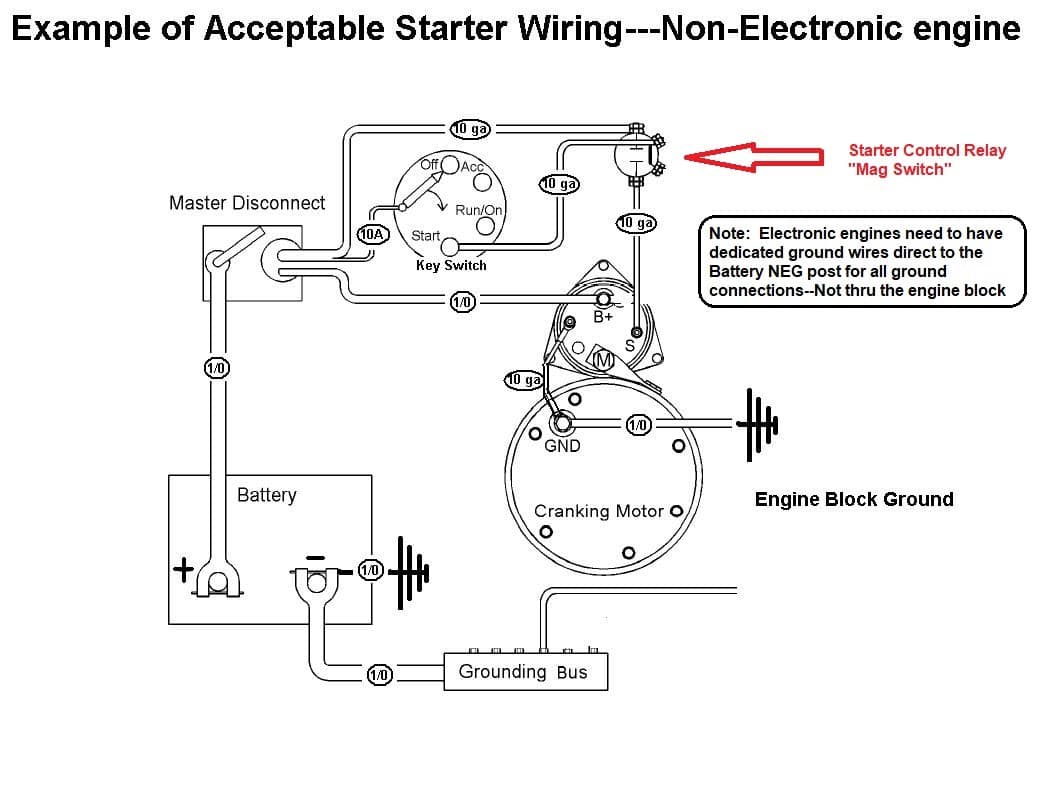

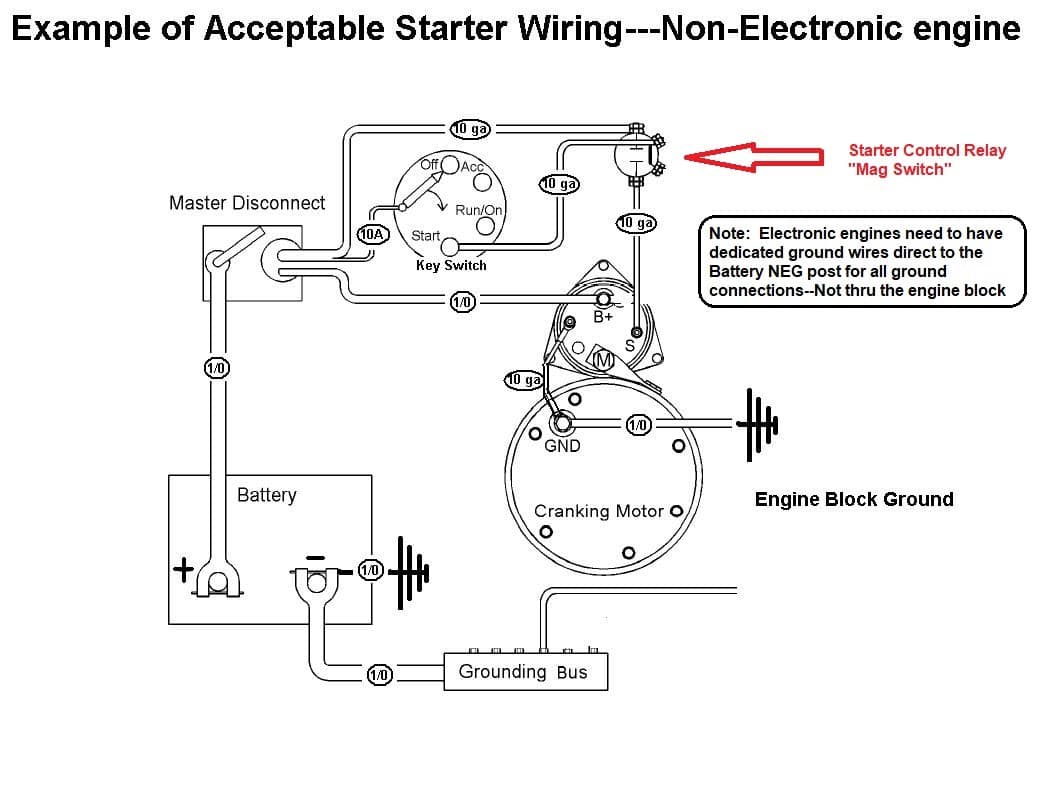

Common Wiring Diagram Configurations

- Direct Drive Wiring: In this configuration, the starter is directly connected to the battery and ignition switch using heavy-duty cables. It is commonly found in older Cummins engines.

- Remote Solenoid Wiring: In this setup, a remote solenoid is used to control the current flow between the battery, ignition switch, and starter. This configuration can help reduce voltage drop and improve overall starter performance.

- Multiple Starter Wiring: Some Cummins engines require multiple starters due to their larger size or high-demand applications. The wiring diagram for multiple starters involves parallel or series connections, depending on the specific requirements.

Step-by-Step Guide to Wiring a Cummins Starter

Step 1: Gather the Required Tools and Materials

Step 2: Disconnect the Battery

Step 3: Identify the Wiring Terminals

Step 4: Connect the Wires

- Using the appropriate gauge of wires, connect the battery terminal of the starter to the positive terminal of the battery, ensuring a secure and tight connection.

- Connect the ignition terminal of the starter to the ignition switch, following the wiring diagram.

- Connect the solenoid terminal of the starter to the corresponding terminal on the remote solenoid or directly to the battery, depending on the wiring configuration.

Step 5: Double-Check the Connections

Step 6: Reconnect the Battery

- Reconnect the negative terminal of the battery, ensuring a tight connection.

- Following these steps will help you wire your Cummins starter correctly, promoting optimal performance and reliability.

Troubleshooting Common Starter Wiring Issues

- No Cranking Sound: If the starter doesn't produce any cranking sound, check the battery voltage, starter solenoid, and ignition switch for any faults.

- Starter Spinning Without Engaging: This indicates a faulty drive gear or starter solenoid. Inspect these components and replace them if necessary.

- Intermittent Starting Issues: If the starter works inconsistently, inspect the wiring connections for any loose or corroded terminals. Clean or tighten the connections as needed.

Tips for Maintaining Your Cummins Starter

- Regularly inspect the wiring connections for any signs of damage, corrosion, or loose terminals. Clean or replace any faulty connections promptly.

- Keep the starter and its surrounding area clean and free from debris, oil, or other contaminants.

- Monitor the battery voltage and ensure it is within the recommended range. Low battery voltage can strain the starter and affect its performance.

- Follow the manufacturer's guidelines for maintenance intervals and lubrication requirements.

Conclusion

FAQs

cummins starter wiring diagram electrical wiring diagram dodge.

online chat urge on instant workshop reference book download all the summit zenith makes repair manuals bolster manuals workshop manuals ecp diagnostics download now.

cummins ism wiring diagram wiring diagram.

search compare and get hold of high character it solutions in one place get instant entrance to exclusive offers discounts on our webshop.i need a starting system wiring diagram opinions dodge.

find parts cummins search faster better smarter.starting system wiring diagram youtube.

get wiring map attain realize instant mood info at izito now.diesel starter wiring diagram wiring diagram.

feb 18 2020 this pin was discovered by michele f jordan radio wiri discover and save your own pins approaching pinterest.

starting 91 cummins bypassing factory wiring youtube.

cummins signature isx w cm870 control module electrical wiring ism cummins wiring diagrams x4e6v81og8n3 cummins ism w cm876 control module wiring diagram laminated ism cummins wiring diagrams cummins diesel engine diagram ecm images e993 com isx wiring diagram wiring schematic diagram.freightliner starter solenoid wiring diagram wirings diagram.

on the starter relay 35 is the input from the ignition and 36 is the arena for 35 87 is supposed to be hot either all the period times or following the ignition is more or less this is my assumption i would take up its hot all the era and 30 goes to the starter i put 12v directly to this membership and it kicked right over.

volvo penta 3 0 starter wiring diagram wiring schema.

starting system wiring diagramamazon printed bookshttps www createspace com 3623931amazon kindle editionhttp www amazon com automotive electronic diagn.kubota wiring diagram pdf clear wiring diagram.

26 09 2017 a wiring diagram is a streamlined established pictorial depiction of an electrical circuit according to my 1972 wiring diagram the blue wire following lighthearted green hash marks will 1996 chevy the supplementary further controllers are wired similarly a wiring diagram to link join the gsc300 model to the perkins electropak is shown below.

cummins allison,cummins appliance,cummins apparel,cummins atlantic,cummins and partners,cummins arabia,cummins avondale,cummins adelaide,cummins air compressor,cummins allison conversion,starter adalah,starter acg,starter acetobacter xylinum,starter account genshin impact,starter arknights,starter arang,starter alola,starter avanza tidak menyala,starter aerox mati,starter and alternator,wiring adalah,wiring artinya,wiring ac mobil,wiring ac split,wiring access door,wiring alternator,wiring ats,wiring abang,wiring avanza,wiring arduino online,diagram alir,diagram adalah,diagram alir penelitian,diagram alur,diagram alir adalah,diagram angka,diagram activity,diagram alir online,diagram alir proses,diagram alur adalah